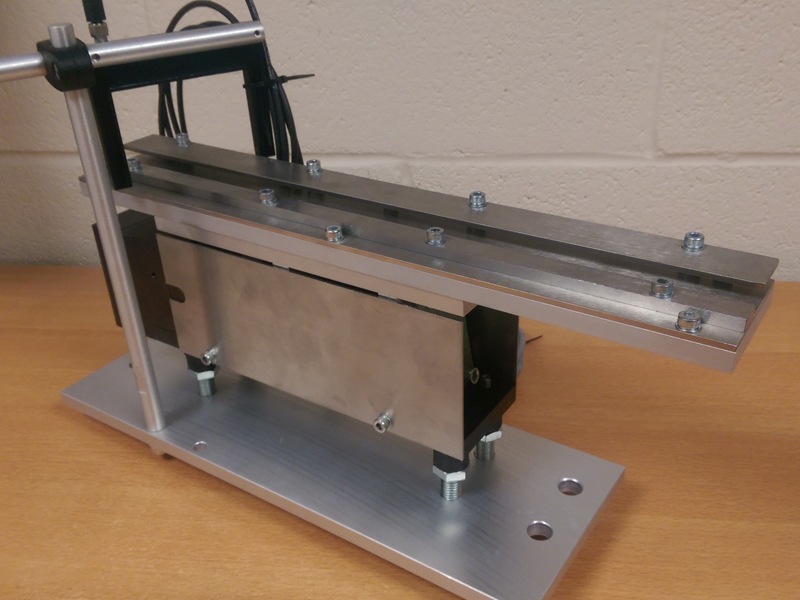

Vibratory Linear Feeder

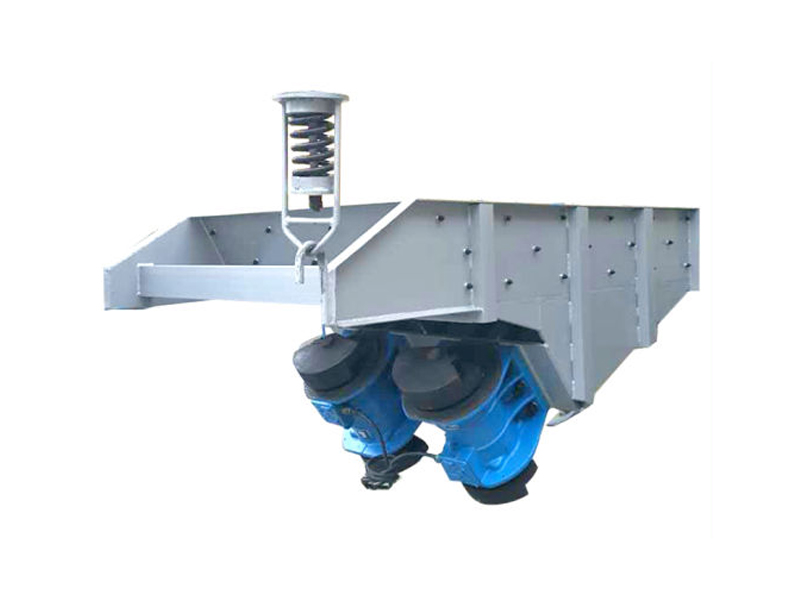

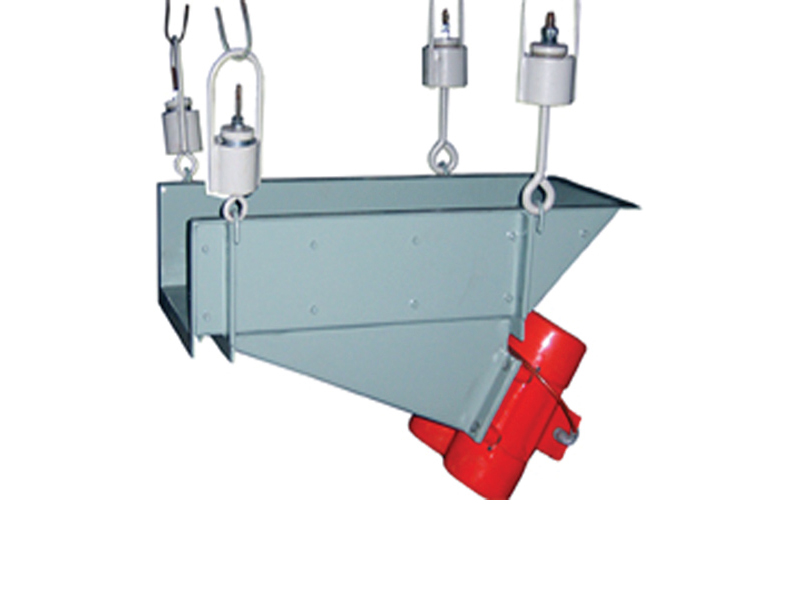

The electromagnetic vibratory feeder consists of a tray made of MS/SS and a body housing the electromagnet. The tray which is connected to the armature of the magnet vibrates as the magnet gets energized. The vibration sets the material in motion. Controlling of voltage gives the controlled flow of the material. The body housing the electromagnet is made in the totally enclosed design to prevent damage by dust. Useful to any continuous process industry where an automatically controlled flow of material is required.

ApplicationElectromagnetic vibratory feeders are very useful in plastics, rubber, food, pharmaceutical, chemical, fertilizer, glass, and other allied industries.

Electromagnetic vibratory feeders can be supplied from a few grams to 100 tons per hour capacity or more. They can also handle slightly wet material. Electromagnetic vibratory feeders can also be used for screening by fixing a screen over the tray.

These screens have been very successful for screening free-flowing materials, as the use of moving parts, eccentrics, etc. have been completely eliminated in this application.

The vibratory feeders tabled below, operate at 230 Volts A.C. single phase system. The bigger size feeders beyond 100 T.P.H operate at 440Volts A.C. Two phase.

|