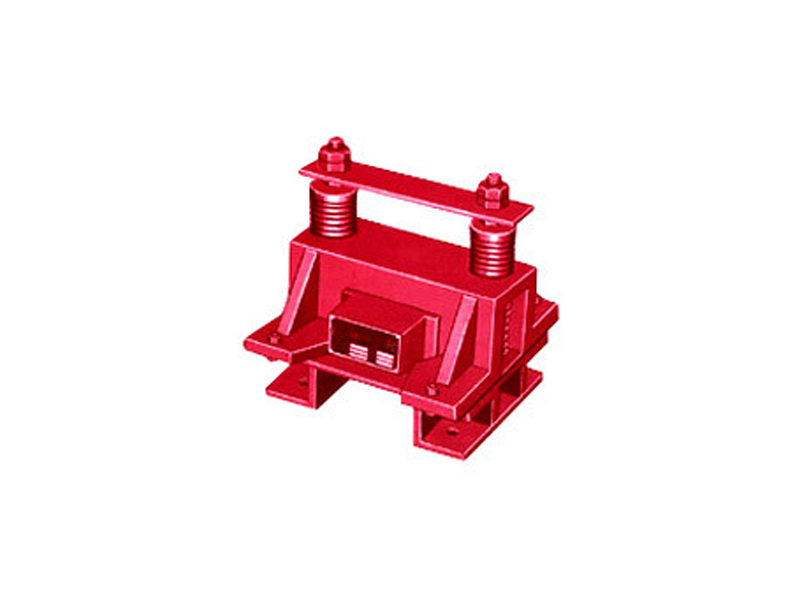

Impact Type Vibrator

The electromagnetic impact type vibrator consists of the main body which houses the coil. The coil is fed with a pulsating current that sets in the vibration. The amplitude of vibration can be controlled by controlling the input voltage. The vibrators are easy to install and use and need no maintenance. The intensity of vibration can be varied if needed by providing regulator in the control panel. Most ideal for declogging of hoppers and chutes Used for conveying products which will not normally move on the slope

Application

Vibrating table is very useful in several industries.

For inclined discharge chutes to produce an easy flow.

For rectangular or cylindrical bin with center discharge.

For effective packing of fluffy and difficult to handle powder in the chemical and pharmaceutical industry.

For proper flow of material in the conical shaped hopper.

Capacity

| The vibrators are made in various power ratings ranging from 25 Watts. to 500 Watts. It is important to use the vibrator of the correct rating. | |

| The vibration model depends on the wall thickness of the hopper. | |

| The design and the capacity of the hopper determine the number of vibrators to be used. | |

| When more than one vibrators are required to be installed on one hopper, they should be connected in the same phase. | |

| All the vibrators are designed to operate at 230 Volts. A. C. single phase system. | |

| The vibrators at higher voltage can be manufactured on request. | |

| Each vibrator will be provided with a control cabinet to convert A. C. to pulsating D. C. except model SDV- 1 |

| Vibrator Model | Capacity Cubic meters | Wall thickness of Hopper. | Power Consumption |

| SDV- 1 | 0.05 | 1 mm. | 25 Watts. |

| SDV- 2 | 0.25 | 2 mm. | 50 Watts. |

| SDV- 3 | 0.5 | 3 mm. | 100 Watts. |

| SDV- 4 | 1 | 4 mm. | 200 Watts. |

| SDV- 5 | 1.5 | 5 mm. | 300 Watts. |

| SDV- 6 | 2 | 6 mm. | 400 Watts. |

| SDV- 7 | 3 | 7 mm. | 500 Watts. |